Our mineral processing customer cases

Gold Ore Processing

Gold ore processing typically involves six steps. A gold ore processing plant uses one or more steps in combination to process gold ore.

Crushing: Sometimes gold is encased in rock particles, and crushing can release the gold. Crushing can also control the particle size of ore and increase the degree of mineralization to meet the needs of different mineral processing.

Washing: Washing is a key step in gold ore processing. Trommel scrubber (gold trommel) is usually used to wash gold ore, remove attached mud and improve extraction efficiency.

Gravity separation: The density difference between gold and other gangue is large, and gold ore can be efficiently enriched through gravity separation. Gravity selection is applicable to both rock gold and alluvial gold. At the same time, the gravity separation equipment is simple to operate, has low investment, and has no secondary pollution.

Flotation: Flotation is suitable for gold ores containing sulfide. During flotation, the buoyancy of the bubbles in the water floats the gold-containing sulfide minerals, thereby achieving the purpose of separation. Flotation can effectively enrich gold and other valuable minerals and improve the recovery rate of gold.

CIP: Also called carbon slurry gold separation process, activated carbon is used to directly absorb and recover gold from cyanide slurry. CIP has a high adsorption rate and a wide range of applications. It is one of the most commonly used and mature methods for treating gold mines.

CIL: It is one of the cyanide gold extraction processes developed based on the carbon slurry process (CIP). The characteristic is that it performs leaching and adsorption at the same time, which simplifies the steps of the CIP process.

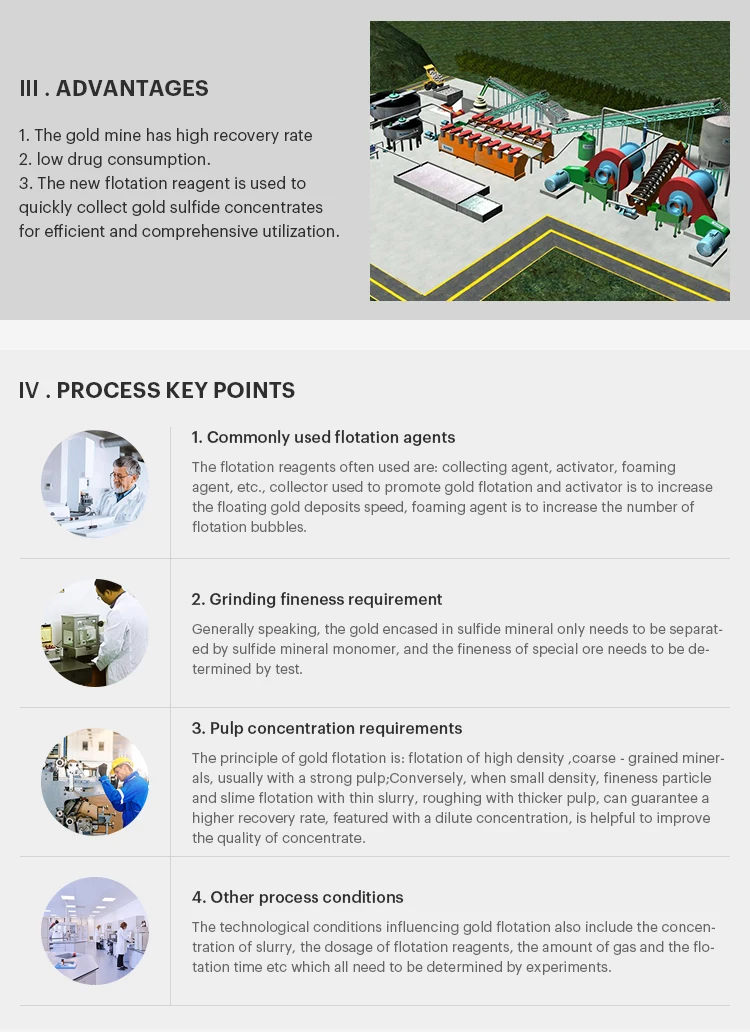

I . GOLD ORE FLOTATION PROCESSING PLANT

According to the differences of physical and chemical properties of gold ore surface, gold ore flotation production line is treated by flotation reagents, the gold deposits are selectively stick to the bubbles for the purpose of separation.

Gold flotation process is divided into several parts, such as crushing, grinding and flotation etc.It will be used jaw crusher, ball mill, spiral classifier, flotation machine, the mixing tank, thickener and other equipment.

II . APPLICATION SCOPE

Vein gold ore; Sulfide gold ore.In addition to separate gold, the process can also be used for flotation of copper ore, lead and zinc ore, fluorite ore, feldspar ore, graphite ore, tungsten ore and other metals and non-metal ore.

600TPD gold ore flotation plant customer case

Gravity separation process is the use of mineral density and particle size differences, with the help of the dielectric fluid and all kinds of mechanical force combined to cause appropriate loose layer and separation conditions, in order to gain the technological process of different density and different particle size of products.

After a comprehensive analysis of test and experiment, mechanical engineers of Xingyang Mining Machinery Manufactory determined the multi-stage grinding and flotation mixed dressing method, specific include: three-stage of grinding, a roughing, secondary scavenging, and fifth concentrating .

After processing, the gold ore grade of from original 5% - 13 % increased to 90% of concentrate. The main equipment of this project includes: jaw crusher, ball mill, spiral classifiers, flotation machine, thickener, mixing tank and other equipments.

I . GOLD CIL PROCESSING PLANT

Gold CIL (Carbon in Leach)leaching process, namely Carbon leaching extraction, it is a process of adding activated Carbon to the slurry and simultaneously leaching and adsorbing gold. This process including leaching pulp preparation, cyanide leaching, activated carbon adsorption, the electric shock to get gold mud, to take off the gold charcoal recirculation, leaching slurry processing etc other seven operation stage.

II . APPLICATION SCOPE

Large scale gold ore dressing, the gold ore which associated more silver and copper.

1200TPD gold ore CIL customer case

This is our factory in Sudan project, The project adopts cyanide leaching gold extraction technology (CIL). The design scale is 60,000 tons per year, 200 tons per day, 300 working days per year.

This gold mine grade is 2-5g per ton, due to its low grade and complex surface mineral property, it is difficult to maintain a high recovery rate in normal operation. Our mechanical engineers comprehensive analysis finally determine to use: CIL cyanide leaching gold extraction process.

Raw materials through crushing, grinding processing, when the particle size of 200 mesh content reach to 90% - 95%, stir and cyanide the slurry, then leaching, activated carbon counter current adsorption, gold loaded carbon desorption electrolysis etc steps, the finished product is gold ingot.

I . GOLD ORE GRAVITY PROCESSING

Gravity separation process is the use of mineral density and particle size differences, with the help of the dielectric fluid and all kinds of mechanical force combined to cause appropriate loose layer and separation conditions, in order to gain the technological process of different density and different particle size of products.

II . APPLICATION SCOPE

It is mainly used for the treatment of alluvial gold, as well as in combination with other types of mineral processing techniques.

In addition to deal with gold processing, it can also be used for processing tungsten ore, tin ore, manganese ore, titanium ore, tantalum niobium ore, barite, Iron pyrite, antimony, chrome ore, etc.

Henan Xingkuang Machinery Co., Ltd., is a large sized joint-stock enterprise integrated with the scientific research,production and sales of heavy mining machinery. The company have five standard heavy industrial workshops covering 80,000 square meters,more than 160 machines used for gold processing,plug welding and assembling with large and medium sizes, and more than 500 works including over 50 administrators with intermediate and senior title and engineering technicians.

Q1: Hi, are you mining machinery manufacturer?

A1: Yes, we can also provide amples test, mine design, equipment manufacture, after-sale service, etc.

Q2: Which country have your products been exported?

A2: Many countries,such as India, Sudan, South Africa, Zambia, Congo, Ethiopia, Iran, Kenya, Mexico, Canada, the United States, Morocco, etc

Q3: Can you do mineral processing test?

A3: Yes, not only do it in your country, but also back to our company

Q4: Can you provide me a solution and quotation?

A4: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage of final products, etc.

Q5: Can you provide me a solution?

A5: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage of final products, etc.

Email: GROUPXKJ@gmail.com

WhatsApp: +8616691620066